Production

At HBS, we are seriously passionate about supplying the finest nuts and dried fruits to our customers. We want to be recognised for the quality of our products and for offering value and efficiency, so we’ve invested in bespoke and purpose-built technology for production, storage and quality control.

Our facilities

We operate out of a BRC AA grade production plant and storage facility, which was designed and built in 2015 to meet our rigorous standards and enable us to deliver on our ambitious growth plans.

Our 20,000 sqft processing plant features totally unique and bespoke processing lines, developed using the extensive industry experience and knowledge in our team.

Equipment

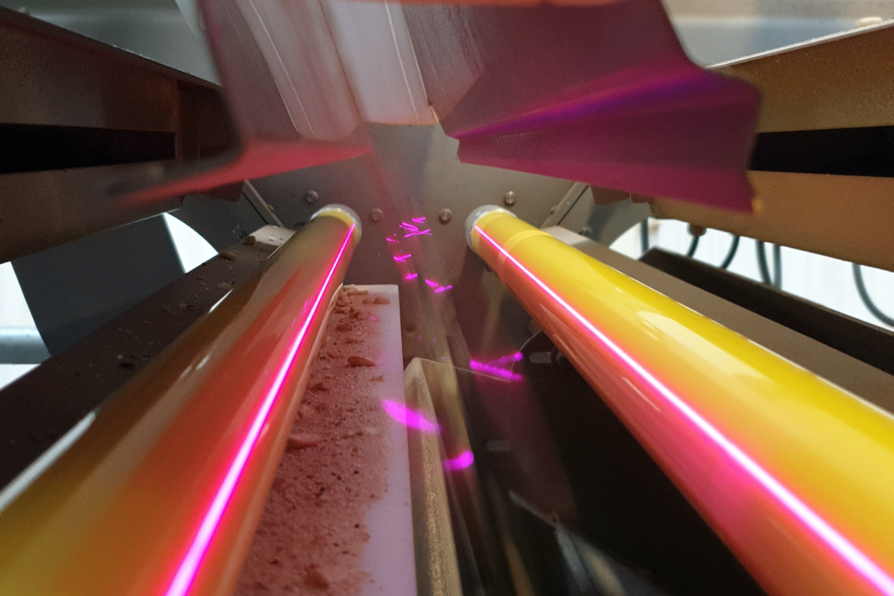

Production begins with the finest laser sorting equipment available, which is vital in all nut production processes. We have a wide variety of processing lines, as well as cutting edge nut pasting lines, meaning we can offer almost any style of nut, butters and pastes to suit all customer requirements.

Safe guarding

We process all products on lines that have been risk assessed. Following the guidelines of our BRC accreditation, products are checked using the latest laser scanning equipment and metal detection units, whilst being overseen and tested by our quality team. To further ensure products meets safety and regulatory requirements, we also undertake hazard analysis, including critical limits, pre-requisites and good manufacturing practices.

Storage

We have a dedicated 22,000 sqft storage facility, which regularly holds over two million pounds of raw materials sourced from approved suppliers all over the world. With space for over 1,600 pallets, we are able to process most orders quickly and efficiently. As part of our standard storage policy, we have product segregation in place for organics, dried fruit, tree nuts and ground nuts.

Quality Control

Our on-site quality assurance and control team oversee all production and ensure that our customers receive only the highest quality products. The team constantly scrutinise all aspects of our business and processes, carrying out robust in-house audits to ensure policies and procedures are not only met but remain modern and fit for purpose.

We have an advanced laboratory on site where chemical and quality tests are carried out, helping to maintain our high standards. We use external UKAS and NAMAS accredited laboratories for micro testing. We demonstrate our consistent technical excellence through our compliance with the highest food standards. We are a BRC accredited company, which also means we only use suppliers that have been audited by ourselves or by accredited brokers.

As a supplier to some of the UK’s largest food brands, we regularly undergo spot audits by our customers.

Site Security

For peace of mind and to meet current BRC food safety requirements, our secure site has access controls for vehicles and personnel. We also monitor all movements and processes throughout the site with a highly sophisticated CCTV system, in conjunction with personnel monitoring for employees and visitors. Deliveries, storage, production and despatch are all monitored and recorded by our 24/7 security system.